The digitization of rail

#01

Modular structure

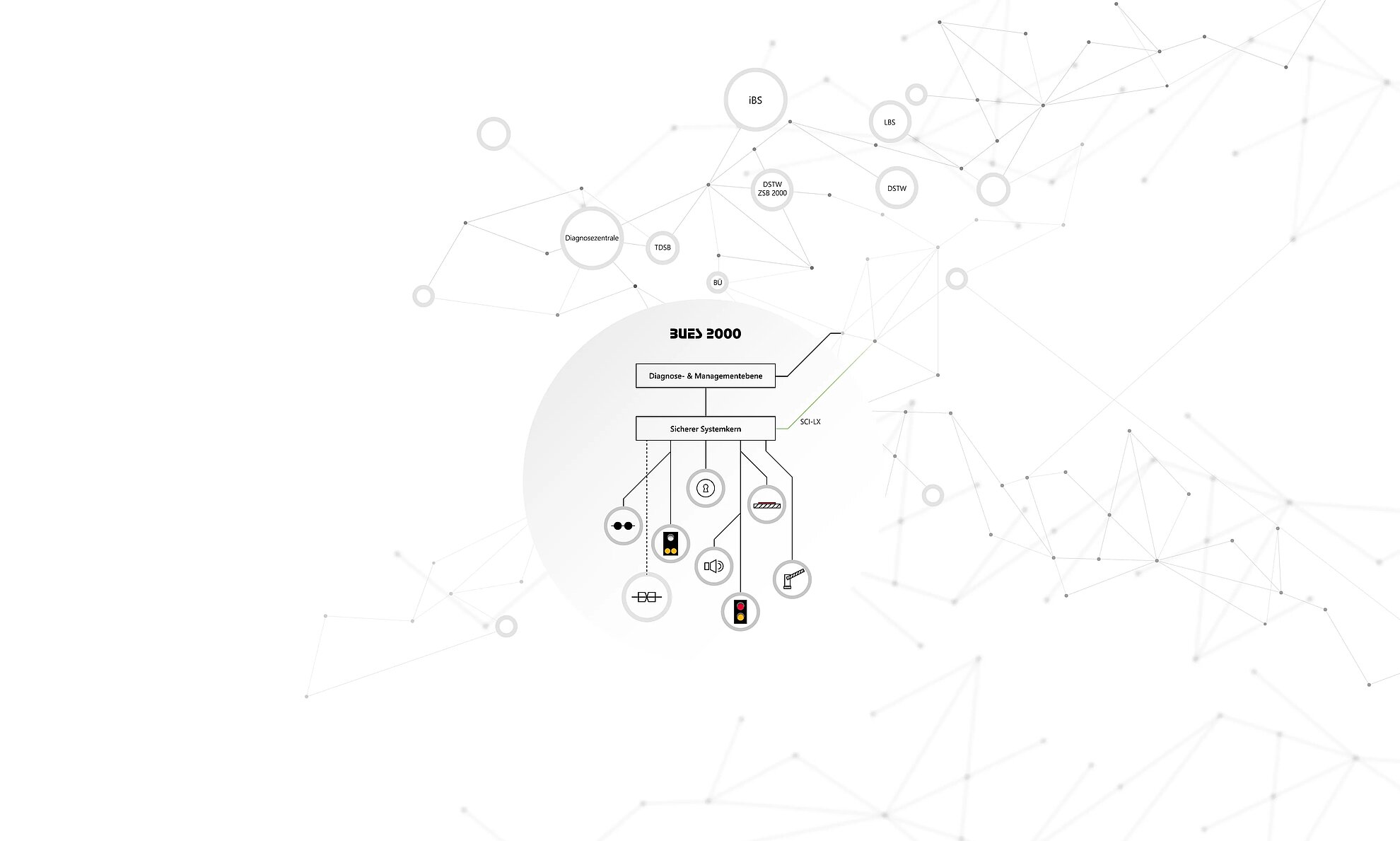

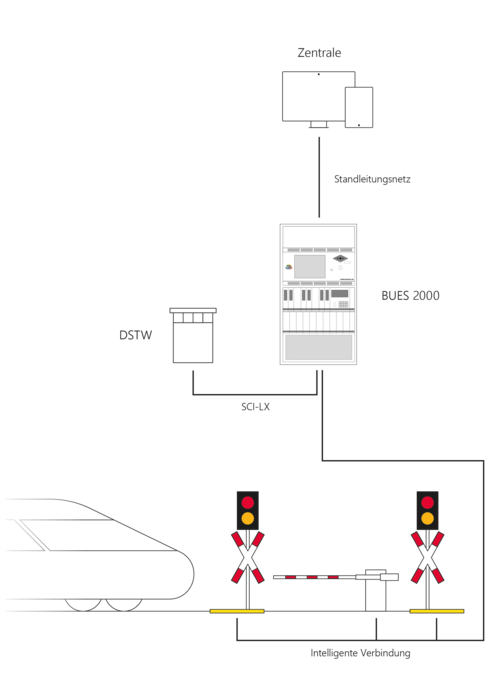

The concept of the BUES 2000 works according to the principle of distributed intelligence. Information is transmitted from digital field components to a safe system core. From that point, the information is processed and the appropriate commands are transmitted to the field components.

Intelligent system solutions

Securing traffic flows is a major challenge, especially at crossing points, as demands on the safety and availability of technical facilities are constantly increasing. Level crossing protection systems are components of railway signalling technology and are responsible for reliably securing road and rail traffic crossing points.

The standard in the level crossing protection system market

Already etcs-ready thanks to the use of digital modules and the latest communication technologies.

With 150 years of experience in railway signalling technology, the BUES 2000 digital level crossing protection system is equipped with intelligent field components that include:

- Road signals, (yellow/red light signals, flashing lights, double flashing lights, etc.)

- Monitoring signals

- Axle counters

- Vehicle sensors

- Barrier drives

The system defines the standard in the market for level crossing protection systems. With more than 5,000 BUES 2000 systems installed worldwide, the flexibility, competence, and experience of Scheidt & Bachmann Signalling Systems in the field of level crossing protection technology have been proven time and again.

Due to the consistent use of digital components, diagnosis and control via modern and intelligent communication paths have become standard.

Intelligent field elements make it possible to outsource control and monitoring tasks. This means that more information can be processed and recorded on a decentralised basis and made available for more efficient control of the entire system. This information is used for state-of-the-art system diagnosis. Maintenance and diagnostic tasks can be centralised by using public or private communication channels. Furthermore, digital data connections such as EULYNX SCI-LX (Standard Communication Interface for Level Crossings) can be easily established by means of RaSTA (Rail Safe Transport Application) secured via IP-based networks, whereby an intelligent link to neighbouring interlocking systems is possible.

Modern methods also make it possible to exchange information with the vehicle, as all the data are intelligently made available at any location and there are no limits to the amount of information that can be processed. The system forms the basis for the integration of BUES 2000 into ETCS.

A suitable system solution for every railway transition

Scheidt & Bachmann products for the central diagnostic level

Diagnostic and maintenance concepts for technical systems are becoming increasingly important. We invested in the development of a digital system concept at an early stage. The digital system structure of the BUES 2000 and the intelligence of the components and field elements have made it possible to build up a concept that provides a high density of information for diagnosis and maintenance purposes.

Scheidt & Bachmann products for the intelligent safety level

All processes at the BUES 2000 level crossing that involve the safe acquisition, processing, evaluation and output of information, coupled with detailed information for the diagnostic interface, are implemented by this technology exclusively via digital modules. In order to meet the respective use cases required for a level crossing, a modular concept of distributed intelligence has been implemented. The individual modules are adapted to the customer-specific applications by means of parameterisable software. Special-purpose software tools are used that simplify the project planning of a BUES 2000 and enable effective digital tailoring to meet customer requirements. As a result, the hardware modules are identical for all monitoring and application variants as well as for all markets and customers, which means a great simplification for innovation processes, type support, service and parts storage.

Scheidt & Bachmann products for the intelligent field level

Following the concept of distributed intelligence, intelligent digital field elements are used in the BUES 2000. In addition to the control function, these field elements can also perform a multitude of evaluation, monitoring and diagnostic functions. For example, the axle sensor is evaluated directly on the track and the LED light points in the light signs and signals independently monitor whether they are sufficiently bright.

LX-Ready

All BUES 2000 systems can be upgraded to LX. LX enables very simple integration of the BÜ into ETCS.

Was bedeutet LX-Ready

- Alle BUES 2000 sind grundsätzlich auf LX hochrüstbar. Jede neu gebaute BÜSA sollte optimal für eine LX-Schnittstelle vorbereitet sein

- LX ermöglicht eine einfache Integration des Bü in ETCS. LX-Ready bedeutet auch ETCS-Ready

- Vorerst wird die Anlage mit klassischer Sicherungsart (Üs, Hp, Fü) in Betrieb genommen

- Später kann die Anlage mit minimiertem Aufwand auf SCI-LX (FSÜ) umgerüstet werden

BUES 2000 LX-Ready: Vom Kunden zu beachten

- Achssensorik bestellen/planen

- Ausrüstung mit passender Stromversorgung bestellen:

- Wenn FSÜ-Überwachungsart noch unklar, immer eine Fü-Innenanlage bestellen

- Anlagen die in Zukunft FSÜ(B)-Anteil haben, immer mit Fü-Innenanlage bestellen

Status BUES 2000 mit SCI-LX

- BUES 2000 Software verfügt bereits über die SCI-LX Schnittstelle (FSÜ)

- Erste Tests mit Stellwerken von Marktbegleitern wurden durchgeführt

- Erste IBN voraussichtlich in 2024

Intelligent barriers

#02

Intelligent barriers Product innovation: HSM 10E

Our HSM 10E hydraulic barrier drive is a compact, modular and intelligent drive system. The HSM 10E has been in operation in Germany and Europe for many years and has now been modernised with a revised drive module that features greater power reserves and higher availability.

The HSM 10E is designed for barriers of 1-10 metres in length and can also be operated with larger barrier arms in certain cases. Using hydraulics, a compact, maintenance-free system has been implemented, which enables safe spare closing up to the lower end position.

Structure:

- Modular construction with subsystems that can be exchanged on site: Housing, boom shaft, drive unit and control electronics

- Use of standard hydraulic components from the aviation industry

- Contactless position detection with high resolution

- Environmentally friendly hydraulic oil with particularly stable temperature behaviour

Behaviour during operation:

- High power development

- One drive for all barrier lengths

- Reduced operating noise and extended service life due to intelligent smooth running into the end positions

- Spare closing up to the lower end position

- Automatic calibration during commissioning and after power failure

- Selection of different running programmes

Maintenance-free and long service life:

- Minimal number of individual moving parts

- Use of proven large-series hydraulic components

- Large reserves in seals and connections

- Self-lubrication through hydraulic oil

Environmentally friendly:

- Long service life

- Biodegradable hydraulic oil

- Energy recovery when closing the barrier

100% Made in Germany

The new PSB 2000

#03

Modern service concept

Each BUES 2000 level crossing has a diagnostic module that is connected to the safe system core via a non-reactive interface. The diagnostic data received via this interface can be displayed either graphically or text-oriented. The information can also be made available for remote access.

Diagnostic computer

The diagnostic software installed on the local PC processes data received from the BUES 2000 and makes it available to service and maintenance staff. The diagnostic computer is identical to that used in other Scheidt & Bachmann product solutions.

Diagnostic interface

For maintenance personnel, the graphical user interface of the diagnostic system provides an overview of the states of all subsystems of the level crossing in an overview screen. In addition to the display of active status changes, such as the opening and closing of the barriers or the status of the track sensors, faulty elements are also visualised clearly and in real time. Further diagnostic information can be accessed via the menu and analysed by means of online help or additional evaluation tools.

Data exchange

In our networked world, it is of great importance that data is always available where it is needed. The diagnostic system of the BUES 2000 forms the basis for this availability. The diagnostic computer can forward the determined diagnostic data via a wide variety of transmission paths. In addition to leased line-oriented data transmission via copper or fibre optic connections, a wide variety of digital transmission paths such as the internet, telephone and mobile phone networks can also be used. The transmitted diagnostic data can be provided as a website, regardless of location.

Diagnostic centre

In a diagnosis centre, all connected level crossings and interlockings can be monitored simultaneously. The diagnostic data are available in one place and maintenance and servicing operations can be planned and coordinated from there. The software of the diagnostic centre is an application optimised for the requirements of service and maintenance, which can be operated intuitively and does not require any special knowledge.

Signalling

#04

Signaling with LED technology and intelligent acoustics

To inform road users of an approaching train at level crossings, various light signs and signals are used. For this purpose, we offer our SSB 200L signalling system with intelligent LED technology.

The system is modular and available in single-, double- and multi-word versions. In addition to coloured signalling, discs with symbols (e.g. direction arrows) or acoustic warning devices can also be used if required.

SSB 200L intelligent LED technology

By outsourcing control tasks to the field element, the BUES 2000 enables the use of computer-controlled LED signals. These LED signals operate independently and communicate digitally with the BUES 2000. The LED signal contains several LED chains. The LEDs of the individual chains are distributed over the entire surface of the optics. This has the advantage that the failure of a chain has only a minor effect on the illumination and a reflector can be dispensed with. If there is a failure of an LED chain, the intelligent signal transmitter communicates this information to the BUES 2000.

Advantages:

- Very long service life

- Low maintenance

- Simple construction

- Large beam angle

- High luminous efficiency

- Low energy requirement

Equipment:

Modular design with the subsystems interchangeable on site:

- UV-resistant plastic housing

- 200-mm LED panel (red/yellow/white)

- 100-mm LED panel (red/yellow/white)

- Control electronics (LZA-BG)

Further features:

- Failure monitoring of the LED chains

- Fallback management in case of communication failure

- Automatic adjustment to the applied input voltage

- Automatic calibration after a power failure

Track signalling with intelligent LED technology

In the case of level crossing systems that are implemented with the monitoring variants ÜS, ÜSoE or Vk, it is necessary to indicate the proper status of the system to the train driver. Our product range offers appropriate monitoring signals for this purpose.

Monitoring signals

With supervision signals it is important that they can be seen well by the driver, even under difficult conditions. The intelligent LED technology ensures high light efficiency and excellent visibility from long distances. Digital or current-monitored control of the light points is available as an option. This ensures that only valid signal terms are displayed.

Equipment variants:

- BÜ0/1

- So16

- EKÜS

- KL

- F0/F1

With:

- 200-mm LED beacons (white/yellow/bicolour red/white)

- Active 136-mm LED beacons (yellow) or reflector discs

Further features:

- Uniform area illumination

- Wide beam, low phantom optics in accordance with EN 12368

- Housing versions:

- Metal housing (KS 200, angular)

- UV-resistant plastic housing

Intelligent acoustic signalling

Road users at level crossings are usually alerted to an approaching train by means of acoustic signalling devices in addition to the light signals. Our level crossing acoustic signals guarantee an optimal acoustic warning.

It is important that the acoustic signals are clearly audible under all conditions. However, the acoustic level should not have a disturbing effect on the surroundings of the level crossing. In addition to lowering the volume level by means of a timer, our acoustic signals can automatically adjust the output volume to the ambient volume. This feature ensures optimal audibility under all circumstances. To determine the current ambient volume, the loudspeakers are used in the function of a microphone.

The digital level crossing acoustic signals can play a variety of different warning signals that are loaded onto the module via a USB interface. This feature allows the acoustic output to be customised according to the customer’s wishes.

Other features:

- Up to 4 signal transmitters per acoustic module

- Individual sound and time-shifted signal output possible per signal transmitter pair

- 256 different sounds can be called up

- Playback of individual sound files

- Independent failure detection

- Retrofittable for old systems

Track sensors

#05

Intelligence for track sensors

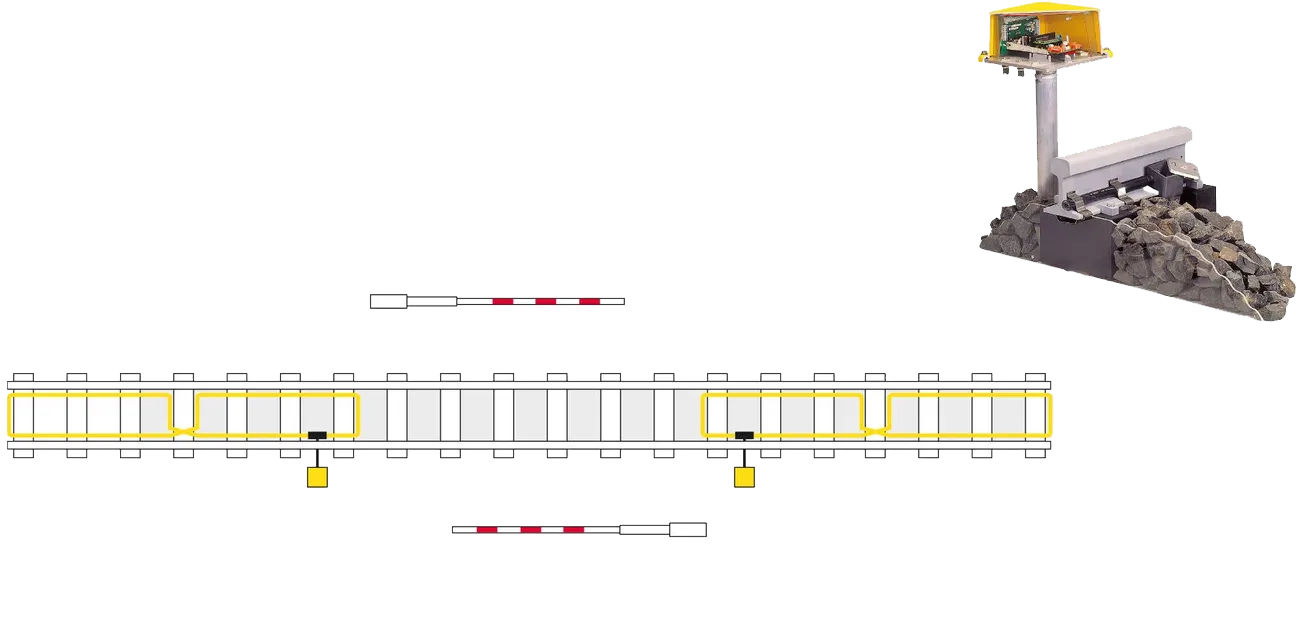

The Scheidt & Bachmann axle counting system is in current use thousands of times across Europe and guarantees safe railway operation. It is used in both the ZSB 2000 interlocking and the BUES 2000 level crossing protection system. The system works self-intelligently and communicates digitally with the BUES 2000. Our axle counting system reports the number of detected axles and their direction to the level crossing, the interlocking, or a train detection system, which takes over the evaluation of this information and initiates the appropriate reactions. A system always consists of:

Axle sensors

An axle sensor consists of two induction loops, which are installed in a compact, impact-resistant and waterproof plastic housing and evaluated in an axle-sensitive manner due to their linear expansion. The component is clamped to the rail with a universal fastening and can be mounted and dismounted very easily.

Axis sensor evaluation unit

The axis sensor evaluation unit evaluates the inductive damping of the axis sensor and digitally transmits each detected axis with the corresponding direction to the superior system. The system, consisting of the axle sensor and the evaluation module, can also be used as a feedback signal. In this case, the feedback signal is output as a galvanically free contact. A digital connection to a superior system is not necessary here.

Equipment:

- Axle sensor as double induction loop

- Impact-resistant and waterproof plastic housing

- Universal fastening for clamp mounting on the rail

- Track connection housing with connection distributor, connection plate and cable gland

- Axis sensor evaluation module for controlling and evaluating the axis sensor signals and for communication with the superior system

Further features:

- Low linear expansion in the track

- Maintenance-free system

- Universal fastening, regardless of rail shape

- Easy mounting and removal

- No adjustment after dismantling the axle sensor (e.g. due to tamping work)

- Independent of superstructure and thus sleepers

- Simple installation without drilling work on the rail

- Only one sleeper compartment distance to other elements in the track necessary

- Continuous and intelligent evaluation directly on the track with automatic recalibration

- Self-diagnostic system with automatic fault indication

- Connection of manual control buttons directly to the axle sensor evaluation assembly possible

- Approval up to 160 km/h, i.e. 100 mph

Consistent train detection

In addition to the Scheidt & Bachmann axle sensor system, we also have the proven and maintenance-free Scheidt & Bachmann 60/80 vehicle sensor, which enables direction-dependent train detection. This train detection system is based on the design principle “simple sensor, intelligent evaluation” and combines the advantages of a simple inductive sensor with the possibilities of digital evaluation.

Equipment:

- Induction loops in the form of an “8” (2 x 5 sleeper compartments)

- Double oscillator module for controlling and signal processing of 1-2 induction loops

- Weatherproof aluminium track connection housing

- Rail foot connection housing for tamping machine-proof installation of the vehicle sensor

- Stainless steel rail foot clamps for various rail shapes

Further features:

- Galvanic separation rail loop

- No influence of rail currents on the loop

- Insulated superstructure; wooden and concrete sleepers only required directly in the area of the loop

- No short-circuit bridges or insulating joints necessary

- Independence from axle shunts, as damping is provided by the iron mass

- No interference by magnetic or eddy current brakes via special cables

Application:

- On/off switching of level crossings

- Connection to:

- EBÜT 80 systems

- EBÜT vB systems

- BUES 2000 systems

Scope of functions

#06

A suitable solution for every country

Since the beginning of the development of digitalised control and safety technology, Scheidt & Bachmann has pursued a modern and flexible platform strategy. The Scheidt & Bachmann platform (PSB 2000) has been continuously developed since then and forms the basis for our BUES 2000 level crossing and the ZSB 2000 interlocking. It follows the concept of distributed intelligence and allows functions and hardware to be decoupled from each other and thus to react individually to even the most varied customer requirements.

The platform consists of:

- The hardware modules

- The associated firmware

- The operating systems

- The generic basic software components, the components are always identical and used for both the BUES 2000 level crossing technology and the ZSB 2000 digital interlocking.

This common platform results in cost-optimising synergy effects, helping to simplify development, approval, production and the supply of spare parts. The same spare parts can be kept in stock for maintaining both the ZSB 2000 digital interlocking and the BUES 2000 level crossing technology, thus minimising parts storage and the maintenance staff can easily be trained for two very similar technologies.

The necessary and often very different functions and requirements of the markets are met by planning the software on a project-related basis.

The platform strategy makes us optimally equipped to implement a broad range of market-specific requirements. The use of BUES 2000 level crossing technology in more than 15 countries without needing to generate customised hardware proves the success of this strategy.

Future-proof setup

BUES 2000 is a digital level crossing protection system characterised by a modular concept with distributed intelligence in all of its components and state-of-the-art networking. This multi-computer system, which features a continuous 2v2 safety structure, makes it possible to control all processes as safe recording, processing, evaluation and output of information as well as a detailed diagnostic interface for maintenance and service purposes.

Its modular structure enables the system to be quickly and flexibly adapted to each monitoring and application variant as well as other individual customer requirements.

Monitoring variants:

- FSÜ(S) and FSÜ(B) Track monitored

- Fü Remotely monitored

- Aut Automatic mode

- Hp Main signal monitored

- ÜS Supervision with signal BÜ 0/1 or So16a/b or EKÜS

- ÜSoE Supervision signalled with optimised switching on

- Vk Availability controlled

- Bed Operator-monitored

- Combinations (e.g. HP-Fü, HP-ÜS, FSÜ(S/B) ...)

Application variants:

- LZ Yellow/red light signal

- Bli Flashing light

- Dbli Double flashing light

- H Half-barrier

- HH Full barrier with 2 half-barriers

- V Full barrier

- F Footpath barrier

- V(A) Call barrier with attendant control

- V(AS) Call barrier with self-service device

Extension variants

The following maximum expansion variants are possible with the basic equipment:

- 64 light signals (yellow/red)

- 64 flashing lights (red)

- Barrier light

- 16 barrier drives

- User-controlled barriers

- 8 pedestrian acoustics (more loudspeakers possible in parallel)

- 2 tracks (with track sensors, signalling and hand control buttons)

- Interlocking interfaces

- 2 GFR danger-zone-free detectors

The following and more applications can also be implemented:

- Special switching cases, such as SF-2 (WS, UW), SF-12, WFS, ESW, EVSTW, DUF and many more

- Time-controlled barriers (H, HH, V) and light signals (LZ, vLZ, Bli, Dbli, pedestrian acoustics) and gate dependencies

- Control of additional light programmes such as BüSTRA

- Extension to 4 tracks

Technical structure

The system core of the BUES 2000 is logically divided into three levels:

- Diagnostic/management level

- Safety level

- Field level

Within the safety and field levels, tasks are divided into three modules:

Central module

Coordinates and controls the level crossing and provides interfaces such as SCI-LX to the interlocking

Light/barrier module

Controls and monitors the road traffic components such as light points, barriers and GFRs

Track module

Controls and monitors the components in the track such as train detection points, manual control boxes and signals

All subsystems communicate with one another via modern digital interfaces and guarantee fault-free operation in this critical area of the infrastructure.

Effective power supply

A safe and efficient power supply for railway safety technology has a direct influence on its availability and the operating costs of the system.

In order to ensure high availability of the power supply, batteries are used as a mains substitute. The power supply of the safety technology and the battery management is handled by the Digitrans II, which features a compact design, low weight and high efficiency.

Equipment:

- 1,000 to 1,400 watts of charging power for secondary DC voltages of 18 V, 24 V, 30 V, 36 V or 60 V

- Very compact design

- Low weight

- High efficiency (typ. 90%)

- Control by means of temperature-dependent charging characteristics

- Display for current, voltage and temperature values

- Operation via integrated keypad

- Complete compatibility with Digitrans I

Further features:

- Adjustable maximum current limit

- Adjustable charging time at gassing voltage

- Display of battery voltage even during mains failure

- Mains failure counter

- Temperature display

- Fault output via relay contact

- Option to cascade multiple DIGITRANS II in case of increased power demand

- Two relay contacts as external interface, e.g. voltage monitoring (LFÜ) or mains failure

- External CAN bus connection (e.g. diagnostics)

- 1-kW class unit without active fan