OUR OWN PRODUCTION

Products Made in Bytča make a great name for Scheidt & Bachmann´s brand

In addition to software development, we at Scheidt & Bachmann also manufacture our own hardware and equipment for systems that make transportation easier for people worldwide. These products are high-quality devices that are manufactured by combining German know-how and Slovak craftsmanship. It's a great combination that has been working reliably for several decades. However, we are constantly improving our processes and looking for solutions to make the work of our employees easier and more efficient in order for them to enjoy it and find it fulfilling.

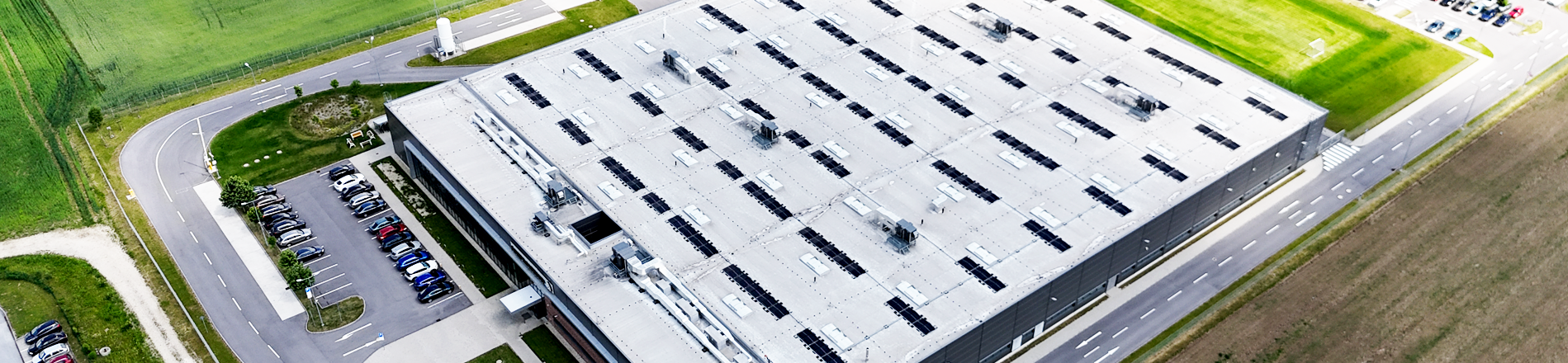

We work as one team and know that we can always rely on each other. We aim to reduce our impact on the environment as much as possible at our production. That's why we have been manufacturing in a modern, environmentally friendly plant since 2020. We also reduce our carbon footprint by manufacturing many of our components ourselves and even recycling some components. By the way, you can find our devices in Boston, London, Strasbourg, Vienna, but also in Dubai and Brisbane.

How we work

You can find 4 departments in our plant:

- production,

- logistics,

- quality,

- purchasing.

Each of them consists of several smaller or larger teams that cooperate with each other on a daily basis.

The purchasing team procures the necessary components and materials. Logistics handles the transshipment, storage, distribution to the individual workplaces and the subsequent transport of finished products to parent company. The production teams produce the components that the assembly workers need to do their jobs. Our colleagues from quality put the finished products to several types of tests to declare the high quality of our products. In addition, we have our own repair centre that provides mechanical and electrical repairs of Scheidt & Bachmann components from all over the world.

We use the 5S system at our workplaces, the Kanban system for supply is realized by the Milk Run train and various smart machines and new-generation systems (Hänel Lean-Lift, mobile shelving systems, customised SAP business management system) help us during our daily work.

And although we have diverse workload, we are all guided by the company's values and each of us contributes to the company's goals with our work.

When we work

We currently work for 1 production shift (6.00 am – 2.30 pm). A move to a 2-shift operation (6.00 am – 2.00 pm / 2.00 pm – 10.00 pm) is planned when the number of orders increases. However, we do not usually work during the nights or weekends.

The management realizes that happy employees are those who enjoy their work. We also have a large number of company benefits and, most importantly, plenty of time for our families and hobbies.

Our gadgets

All our workplaces are arranged with an emphasis on ergonomics, increased work efficiency and faster delivery.

The assembly workplaces have touch screens with technical documentation and assembly instructions. Employees can see the products being assembled via a 3D model which they can rotate, or zoom in/out at any time to understand the entire assembly process more quickly. One of our goals is to gradually replace all printed technical documentation with a digital one, which has several advantages: it saves paper, toner and printing process itself, employees always have the documentation with them and the risk of using outdated documentation is significantly eliminated.

Our next handy machine is the "Milk Run" or Scheidt & Bachmann train. It goes into production at precise times and unloads material at designated stops and loads finished products to take them to the warehouse. In addition, it collects all the separated waste and takes it to the outside container stand.

Join us

Are you interested?

Find out if we are looking for you.